Principle

The Stirling engine is submitted to a load by means of an adjustable torquemeter, or by a coupled generator. Rotation frequency and temperature changes of the Stirling engine are observed. Effective mechanical energy and power, as well as effective electrical power, are assessed as a function of rotation frequency. The amount of energy converted to work per cycle can be determined with the assistance of the pV diagram. The efficiency of the Stirling engine can be estimated.

Benefits

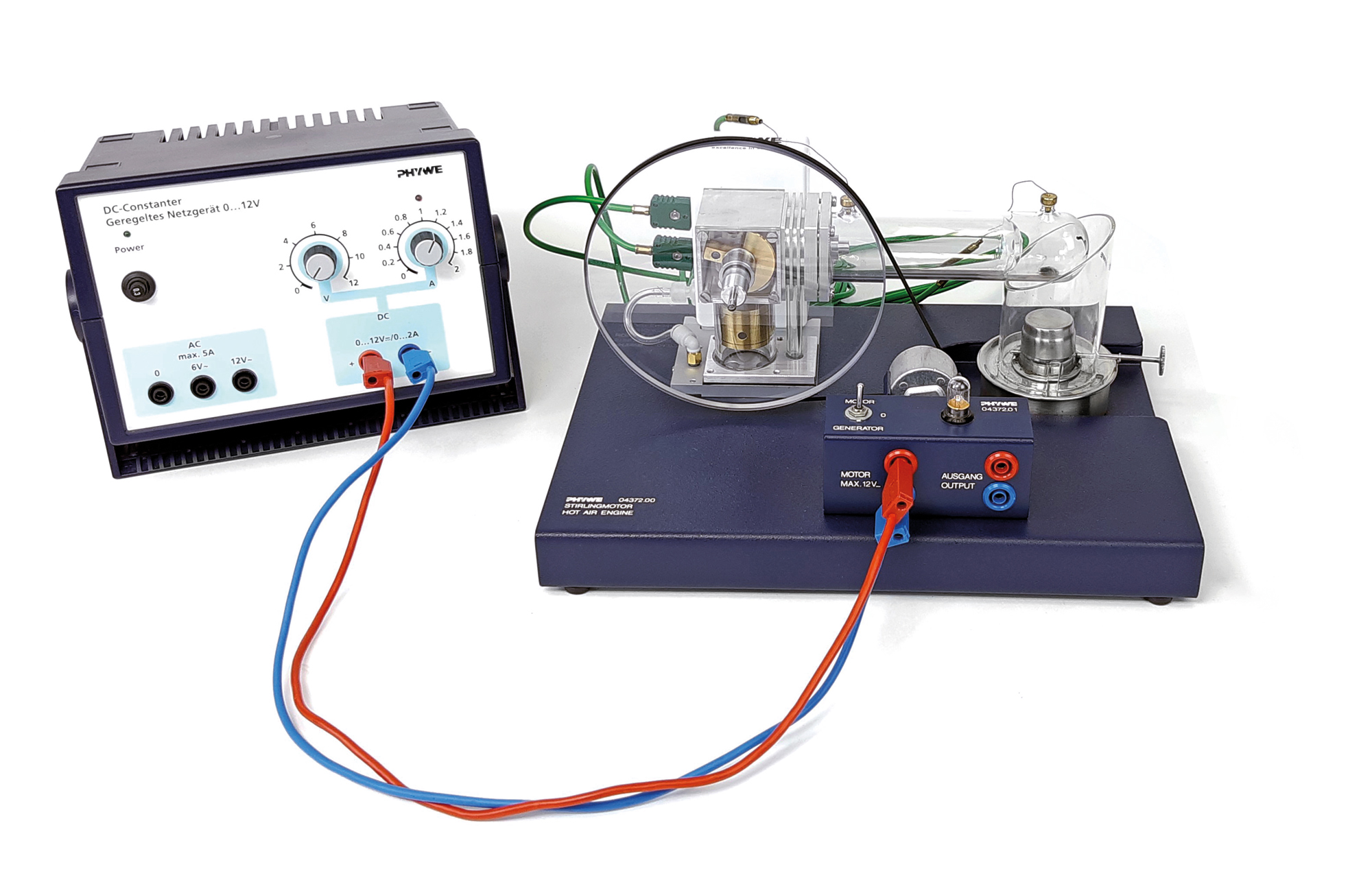

- Demonstration of the complete Carnot process

- Reverse Carnot process possible as well using the motor/generator unit

- All important parts are clearly visible, making their functions transparent

- Measurement device displays all relevant parameters (p, V, rpm, T)

Tasks

- Determination of the burner's thermal efficiency.

- Calibration of the sensor unit.

- Calculation of the total energy produced by the engine through determination of the cycle area on the oscilloscope screen, using transparent paper and coordinate paper.

- Assessment of the mechanical work per revolution, and calculation of the mechanical power output as a function of the rotation frequency, with the assistance of the torque meter.

- Assessment of the electric power output as a function of the rotation frequency.

- Efficiency assessment.

Learning objectives

- First and second law of thermodynamics

- Reversible cycles

- Isochoric and isothermal changes

- Gas laws

- Efficiency

- Stirling engine

- Conversion of heat

- Thermal pump

Recommended accessories

With these accessories you can generate real added value